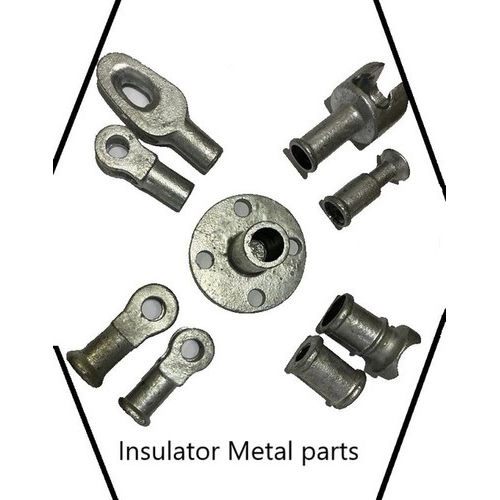

Insulator Metal Parts

Price 110 INR/ Piece

MOQ : 500 Pieces

Insulator Metal Parts Specification

- Thermal Conductivity

- 110 W/mK

- Feature

- Anti-corrosive, durable, precision dimension

- Coating Type

- Nickel or tin plating

- Layer

- Single

- Installation Guideline

- Threaded fitting recommended for secure connection

- Size

- M12 40 mm (customizable)

- Surface Treatment

- Nickel plated

- Density

- 8.4 Gram per cubic centimeter(g/cm3)

- Product Type

- Cap

- Material

- Brass

- Rated Voltage

- Up to 36 kV

- Tensile Strength

- 300 MPa

- Width

- 30 mm

- Thickness

- 10 mm

- Application

- High voltage insulators, switchgear, electrical transmission

- Breakdown Voltage

- Above 18 kV

- Heat Conductivity

- 110 W/mK

- Color

- Golden

- Max Withstanding Temperature

- 350C

Insulator Metal Parts Trade Information

- Minimum Order Quantity

- 500 Pieces

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 6000 Pieces Per Day

- Delivery Time

- Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

About Insulator Metal Parts

We are Manufacturing Dead End Clamp ( 11KV / 45KN / 16FRP ), Tongue & Clevis (45KN / 90KN), Ball & Socket ( 45KN / 120KN),Pin Fitting ( 11KV / 33KV), Post Fitting ( 11KV / 33KV) And Cap/Pedestal (11KV / 22KV) Etc.

Precision Engineering, Exceptional Durability

Each insulator metal part is produced using advanced hot forging and CNC machining to guarantee accuracy within 0.02 mm. The nickel-plated surface, combined with high tensile strength (300 MPa), ensures these parts withstand outdoor elements and high electrical loads, making them ideal for power utilities.

Versatile Application and Customization

These metal parts are perfect for high voltage insulators, switchgear, and power transmission systems. With customizable metric thread sizes and dimensions, they can be tailored to meet diverse installation requirements, ensuring seamless integration into your existing infrastructure.

FAQs of Insulator Metal Parts:

Q: How are the insulator metal parts installed for secure outdoor use?

A: The components are designed with threaded fittings, which allow for a secure and reliable connection. Threaded installation is recommended to maintain optimal performance, especially in outdoor and high-voltage environments.Q: What processes are used to manufacture these metal parts?

A: Production involves hot forging and CNC machining to achieve precision and durability. This method ensures each part conforms to tight tolerances of 0.02 mm and is finished with a nickel or tin plating for enhanced corrosion resistance.Q: When should I choose these insulator metal parts for my electrical application?

A: Select these parts when you require components that meet IS/IEC standards, provide high breakdown voltage above 18 kV, and can withstand harsh outdoor conditions with excellent anti-corrosive properties.Q: Where are these insulator metal parts commonly used?

A: They are widely used in high voltage insulators, switchgear, and electrical transmission systems, particularly in power utilities and infrastructure where reliability and standard compliance are critical.Q: What are the benefits of the nickel-plated surface treatment?

A: Nickel plating provides superior corrosion protection, extending the components service life while maintaining good electrical conductivity. This makes each part suitable for outdoor, high-stress environments.Q: How does the customization of metric threads enhance usage?

A: Customizable metric threads allow the insulator metal parts to fit various installation requirements, ensuring compatibility with a wide range of electrical equipment and supporting secure and efficient assembly.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Insulator Metal Parts Category

Cap Pedestal

Price 111 INR / Piece

Minimum Order Quantity : 500 Inches

Material : Malleable Iron

Product Type : Cap

Features : Good Quality

Application : For Industry

Send Inquiry

Send Inquiry